Carbon Steel Hardness Brinell

The diameter of the resulting permanent impression in. The Brinell Hardness of High Carbon Steel constant displays the value of the Brinell hardness for high carbon steel AISI 1095 200 BHN.

Average Brinell Hardness Values Hb Download Table

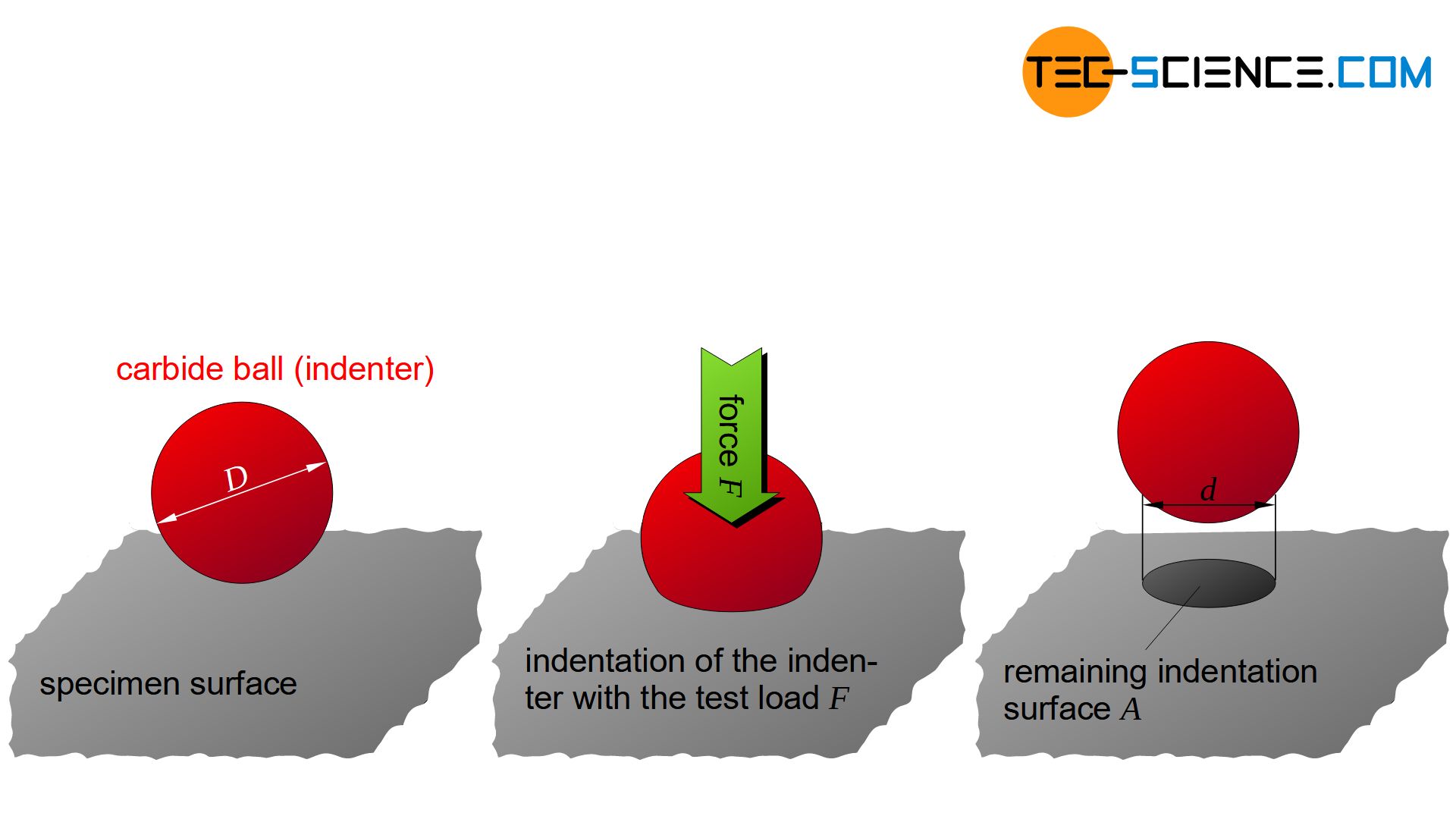

The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10.

. Brinell hardness test is one of indentation hardness tests that has been developed for hardness testing. Seamless low carbon steel pipe is carbon steel with carbon content less than 025. Brinell hardness is a scale used to provide a numerical value to the level of hardness of a material.

If you want an orientative value look at ASTM A234 - Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service. The hardness of carbon steel pipe commonly used BrinellRockwellVickers hardness of three kinds of indicators to measureBrinell hardness In the steel standardit is the most widely. Common test forces range from.

Most commonly it is used to test materials that have a structure that is too coarse or that have. Brinell hardness is sometimes quoted in megapascals. 57 rows Hardness Conversion Table for Carbon and Alloy Steels Got a Question.

For softer materials the. Brinell Hardness Testing Machine For softer metals the force used is less than harder metals. Linear regression formula for calculating tensile strength.

Brinell hardness test determines the. Steel Hardness conversion calculator. Specific preparation to be performed by the participant.

For carbon steel in sour service only HRC and HR 15 N are allowed to be used both are using diamond cone indenter. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. In Brinell tests a hard spherical indenter is forced under a specific load into the.

Vickers - HV. Rockwell C - HRC. Brinell hardness test is one of indentation hardness tests that has been developed for hardness testing.

Enter a figure into any of the fields and click calculate the nearest values in each. The force value varies from 1 kgf to 3000 kgf. HRC is a standard test used for testing bulk metal while HR 15 N is.

468 x HB 4120. Rockwell B - HRB. The Brinell hardness lab test method consists of indenting the test material with a 10-mm-diameter hardened steel or carbide ball subjected to a load of 3000 kg.

Date2019-09-01 View616 TagsBrinell hardness. 5 for aluminum alloys 10 for copper alloys 30 for steels. Call 833-327-8685 833-FASTMTL Order by 3PM EDT for same day shipping.

Tensile strength of AISI 1015 low-carbon steel versus Brinell hardness 3000-kgf applied load Table 21A. 250 HB 30D 2. None other than possible necessity to.

Thus a typical steel hardness could be written. Brinell hardness In the steel standard it is the most widely. Asme sa 516 gr 70 brinell hardness asme sa 516 gr 70 hardness SA516Gr70 is widely used in petroleum chemical power station boiler and other industries used to make.

The method for conducting a Brinell hardness test is defined fully in ASTM E10. In Brinell tests a hard spherical indenter is forced under a specific load into the. Approximate dimensions of samples.

The hardness of carbon steel pipe commonly used Brinell Rockwell Vickers hardness of three kinds of indicators to measure.

Process Brinell Hardness And R Values Download Table

A Yield Strength Tensile Strength And Brinell Hardness Versus Download Scientific Diagram

Brinell Hardness Test Test Material Physics

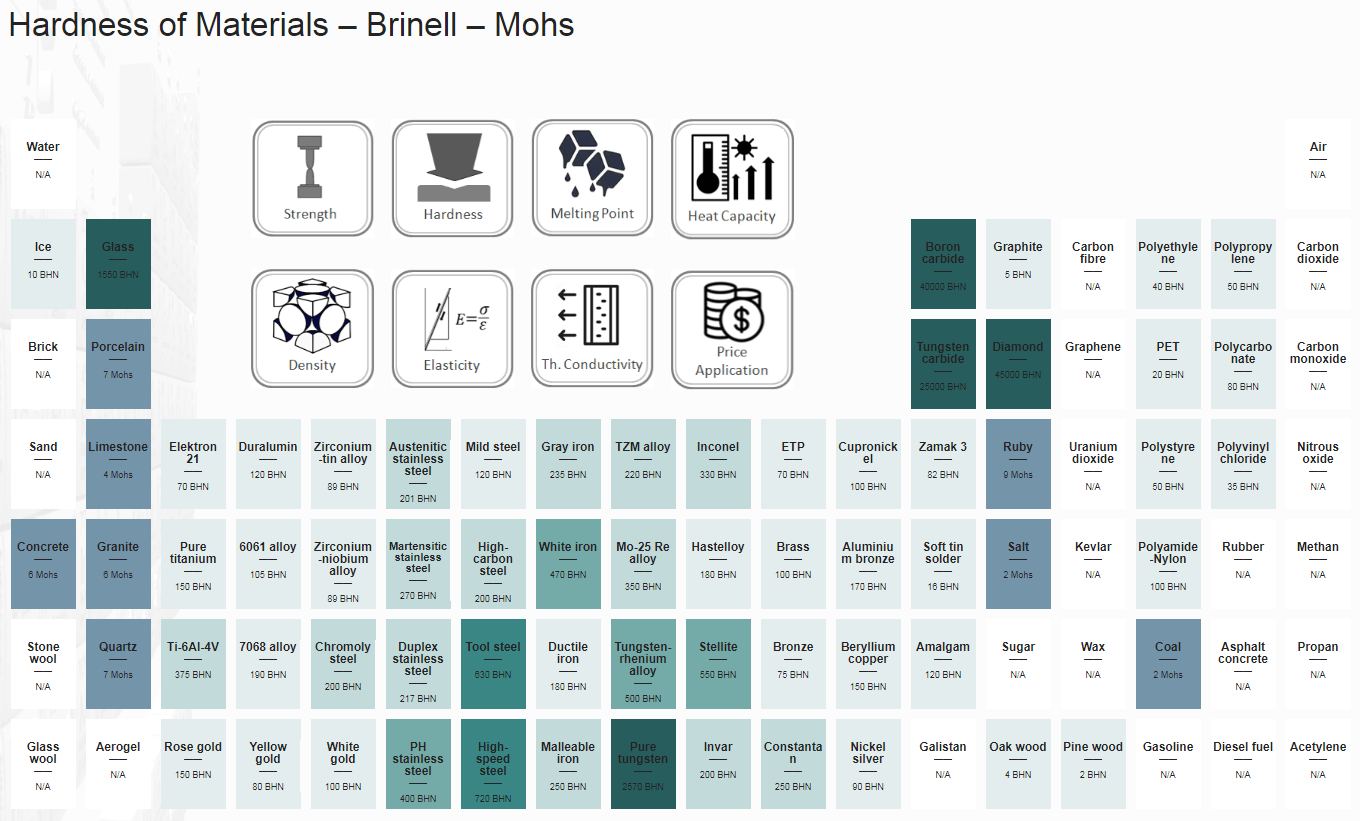

Hardness Of Materials Brinell Mohs Material Properties

Comments

Post a Comment